The GAMMON canard

designed by Gunnar Holm

About the Gammon

The Gammon is a simple rubber powered canard, which is suitable both for the beginner and the

more experienced flyer. In spite of being low-winged, it is very stable.

It has been built in two different sizes, the normal

Gammon with 46 cm span, and the Mini-Gammon which has 33 cm span.

The Mini-Gammon can use a back to front Delta Dart (a.k.a. AMA-Cub or Flugan)

propeller, but then some extra nose weight is needed to compensate for the heavy prop.

Construction

All wood is balsa. The dimensions can be reduced considerably by the

more experienced builder to get a lighter and longer flying plane. A

lightweight version should be able to do 2 mins. without difficulty. Fred Rash's Mini-Gammon, weighing a scant 1.86 grams, actually did 4 minutes! That plane has now been converted to electric power, as shown at the end of this article.

You can either build the structures first, and

then cover them in the normal way, or you can build directly on the covering,

as with a Delta Dart. Use lightweight tissue and

do not water shrink or dope, otherwise the wing will warp.

If the model is intended for outdoor use,

preshrink and dope the tissue on a frame, then cut out and cover (or build

on the doped tissue on the frame).

Note that the flying surfaces are covered only on the underside.

Usually, single sided covering is attached

to the upper side, but here underside covering was chosen for better

turbulating effect.

| |

|

|

| |

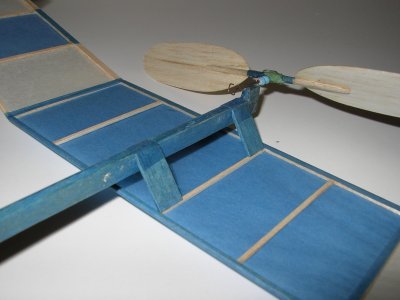

A closeup of the rear, showing the wing and propeller mountings.

The motor stick and wing posts have been covered in tissue.

|

|

|

| |

|

|

| |

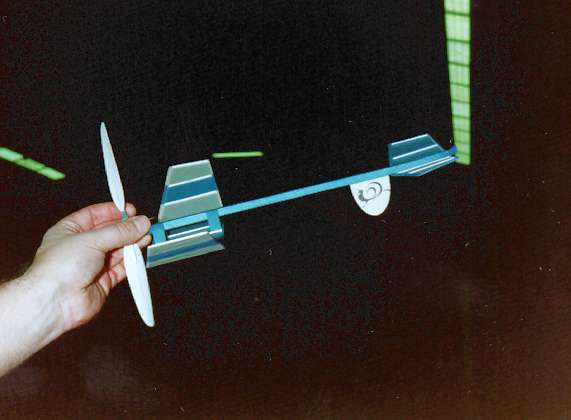

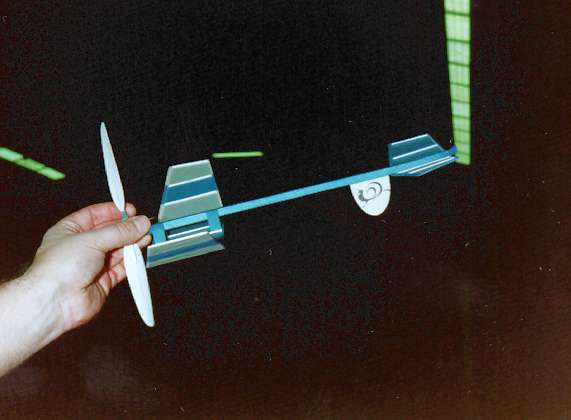

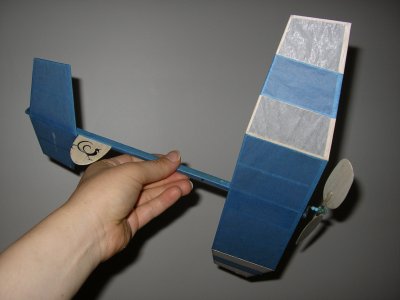

View from below.

|

|

|

Some thoughts by Gunnar Holm about canards

It is important that the stabilizer (front wing) should have a marked stall.

When using curved profiles, the profile of the

stabilizer should preferably have a deeper curvature (the other way round

compared to planes of normal configuration).

When using flat profiles, as in the Gammon,

it is beneficial to have the turbulence-inducing open

framework on the upper side of the stab. surface. The builder is encouraged to

try different profiles. Why it is called Gammon? Well, that is Gunnars

own secret!

About the plans

The plans may come out wrong size when printed. Use a

graphics program, or an enlarging copying machine to get them to the size

you want.

All the measurements given on the plans are for the Mini-Gammon (33 cm span).

The text is in Swedish,

here is some help for the translation:

Mittvinge; central part of wing

Vingspets, vänster; left wingtip

Vingspets, höger; right wingtip

Vingens uppbyggnad i dubbel storlek; Wing construction, 2x enlarged view

Papper endast på undersidan, ....; Do only cover the underside; the

wing is built on the paper, which is then turned over the edges.

Frontvinge; Front wing

TP-läge; Center of gravity (important!)

Bakvänd Fluganpropeller (diameter 14cm); Back to front Delta Dart

propeller (14 cm diameter)

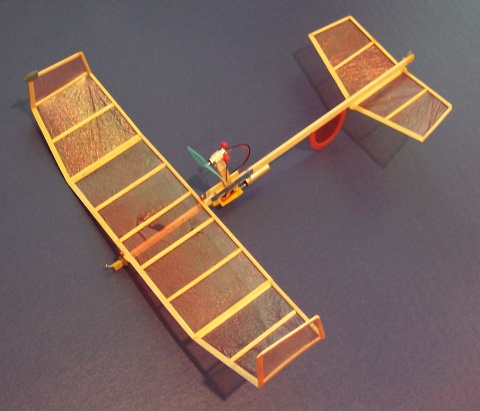

An eletric powered Gammon

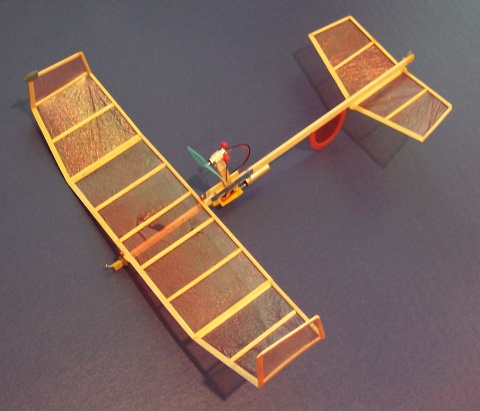

Fred Rash converted his Gammon to electric power, using the motor unit from an Estes Aero-X toy plane.

Instead of batteries, the motor is powered by a large capacity (3 Farad) condensator. Modifications include mounting the wing above the fuselage to be able to use the standard charger,

and adding tip plate fins to the wing. Best flight time with this power unit was 44 seconds.

Here is what Fred writes about his plane:

This canard model was built for rubber power about Christmas 1996 from an easy sport model plan called Gammon by Gunnar Holm. Flat span of the wing before dihedral was 13 inches. The original plan had tissue covering on the bottom of wing and canard and was rubber powered with a plastic pusher prop. I lightened mine a lot from the plans and attached both wing and canard with tissue tubes and small balsa posts. This permitted adjustment of both wing and canard angles and removal for storage. A 0.23-gram balsa prop (5.8" diameter and 9.0" pitch) with molded blades was used.

Indoor Mylar film was dyed with Rit dye and used for covering. Then I didn't know to boil 45-60 min to get more color into the film.

My rubber version weighed 1.86 g, carried about 0.8 to 1.0 g of rubber in a 15-19" loop (about 0.040"), and gave four best flight times of 4:06, 4:07, 4:08, and 4:09. Two of these flights were consecutive, and three different motors were used. The indoor site was the Johnson City, TN, (USA) Mini-Dome with 116-foot ceiling.

This Swedish design was good with rubber power, and I knew CG and incidence, so conversion to Aero-X power looked feasible. I realized that the underslung wing would hang on the standard charger-launcher, so I cut off the wing posts and reglued to put the wing on top

My plan for conversion to Aero-X power was poor. I forgot what many of us have heard: tractor props destabilize and pusher props stabilize. I trimmed the glide to be smooth, but if slightly upset, a vicious Dutch Roll occurred. I broke and repaired the plane several times before I understood. Vertical fin now was needed for stability since there was no big rubber prop. I broke both wingtips at the outermost ribs against the edge of a metal ruler and glued them vertical and this solved the stability problem.

By this time I had broken everything on the plane a few times. You can see the holes in the wing covering. The motor pylon had been broken at least 3 times and I could not reglue it so it was pinned. Persistence paid off, but I was close to pitching the plane into a nearby trashcan.

With a new motor mount and no pins, weight as flown today was 5.37 grams. There were many flights over 30 seconds.

Fred Rash

The Aero-X powered Gammon by Fred Rash. Note the wing end plates which were

necessary to provide som rear lateral aera when not using a large rubber propeller.